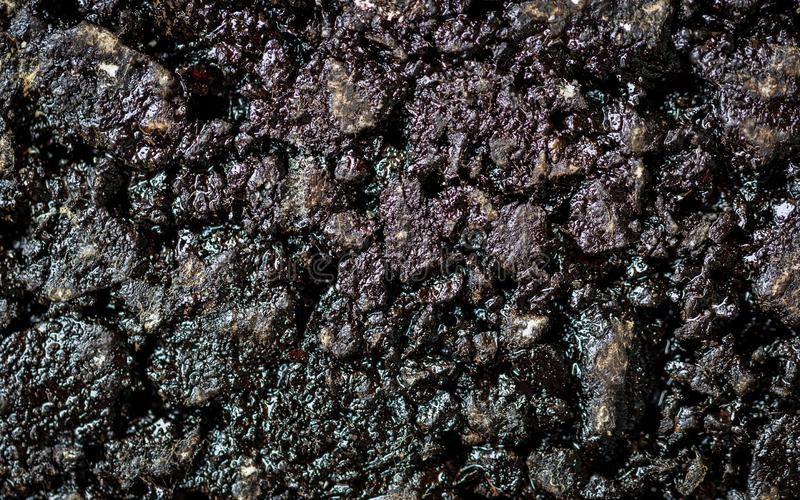

3 Asphalt Driveway Myths Debunked

For generations asphalt has been used as an effective material for paving roads, parking lots, driveways, and more. Despite asphalt’s success, there are still many

For generations asphalt has been used as an effective material for paving roads, parking lots, driveways, and more. Despite asphalt’s success, there are still many

Like most things in life, there is an optimum time for installing an asphalt driveway and completing other forms of repair. There are also certain

These days, more and more builders, homeowners, and remodelers are choosing asphalt driveways over other paving materials. From commercial to residential applications, there’s a reason

Asphalt is a popular choice for any driveway. Not only is it durable enough to last for years with the proper maintenance, it is easy

Your driveway is an integral part of establishing the curb appeal…and even value…of your home. Choosing the right material is paramount for achieving the aesthetic

You’ve likely seen the finished product a million times. But have you ever seen the process of installing an asphalt driveway? Perhaps you’re the “try

We are here to help you decide if it’s time to repair or replace your driveway by weighing the pros and cons of each choice.

Curb appeal matters. In fact, it’s likely what drew you to your home in the first place! And we all know what a huge role

Your driveway is your home’s first impression. And the material your driveway is made of is the biggest contributing factor to how it will be

Asphalt is a mixture of aggregate stones, sand and liquid asphalt cement. But there are several different types of mixtures that you can choose from.

We provide a full set of options for both private and commercial properties. Thanks to our consistent quality, we’ve established a reputation as one of the Greater Toronto Area’s most reputable asphalt paving, interlocking, and concrete construction companies.

© 2020 Epic Paving. All rights reserved.